Implementation of the intelligent computing and decision support systems and shelf life models

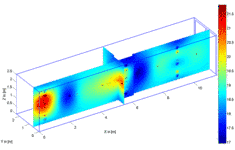

Scope 3 contains the implementation of the decision-making system, i.e. developing algorithms for determining the quality and remaining shelf life. This Decision Support Tool (DST) is supposed to detect potential dangers and deviations from the desired quality at an early stage and take appropriate actions. This may be a correction of set point and airflow in the container, or a rescheduling of the stocks in the subsequent logistical processes.

As first step for the DST implementation, shelf life models for typical perishable food products of our project partners, such as bananas and pork meat, have to be determined. Hereto the parameters of various biological models are calibrated by experiments with samples of the goods in a climatic chamber at different temperatures. The resulting models are verified by experiments in real shipments.

The core of Scope 3 is to implement the DST in a software system that is executable on the sensor system and on the embedded processor platform of the container. The intelligence of the network is shifted to the layer of transport items. By using the OSGi standards as universal middleware (formerly "Open Services Gateway initiative"), it is possible to run the DST vendor-independent on different processors and servers. The task of Scope 3 includes the implementation of a Java virtual machnie on the different target platforms (wireless sensor nodes and vehicle unit).

The DST and system components developed by Scope 1 (sensors for air flow and the gas ethylene) and Scope 2 (telematics units and wireless sensors) will be evaluated in field tests starting in December 2011. Both, container transports by sea (bananas) and road transports in trucks (meat products), are covered.