Field tests

The project was implemented to establish a close link between scientific research and practical cold chain applications. Several field tests were carried out to demonstrate and verify how the developed models, sensors and communications systems operate under the real-world conditions of cold chain logistics. The tests included truck as well as trans-ocean container transport.

Banana cold chain

The remote monitoring of the banana cold chain was tested three times in cooperation with Dole Fresh Fruits. Bananas were packed in boxes in Costa Rica [![]() 1,2]. Some of the boxes were equipped with wireless sensors. Remote monitoring started after palletisation and stowing into the container.

1,2]. Some of the boxes were equipped with wireless sensors. Remote monitoring started after palletisation and stowing into the container.

The container was trucked to the harbour (4 hours), shipped to Antwerp (2 weeks) and transported by truck to Hamburg (1 day). The set points for temperature and air exchange rate were adjusted during the sea transportation by remote access.

Ripening was started after arrival in Hamburg by a technical ethylene treatment. During the next 5 days, the respiration activity increased by a factor of 5 to 10. The progress of the ripening process was monitored by analyses of the temperature curves instead of the usual manual or visual inspections. The set point was remotely reduced step-by-step to compensate for the increased heat production. After 5 days, the bananas were sold to a wholesale trader.

The meat chain

Two field tests were carried out to demonstrate the concept of the intelligent container in the supply chain of meat. For the first test, a truck of the partner company KÜHN-Transporte was equipped with the necessary technical components (Freight Supervision Unit/FSU and Telematics). The transport condition of minced meat was monitored within Germany (Münster to Stelle).

The second tests covered the transport of vacuum-packed lamb saddles from Ireland, via France, to Germany [![]() 3]. Two pallets were equipped with sensors directly after production.

3]. Two pallets were equipped with sensors directly after production.

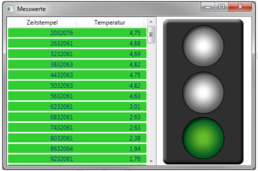

The sensors were started in the offline-mode; temperature data were only logged to the memory. The pallets were transported by truck to a depot in Paris, and from there, transported to the main premises of RUNGIS express in Meckenheim, Germany. At stock receipt in Meckenheim, the sensor data were retrieved and evaluated by a tablet PC to replace manual quality control procedures.

The sensors remained attached to the packed meat during the de-palletisation and consolidation processes. For the subsequent transport, the sensors were switched to online-mode. A truck, equipped with FSU and telematics, was used for the final transport to a retail market in Bremen, via a depot in Landbergen.

The data recorded in the offline-mode showed that all logistical processes in this particular chain, including transhipments and depot handling, complied with the recommended cold chain conditions. Whenever means of transport are equipped with telematics and interfaces to connect to the wireless sensors, the online-mode can be used. Information about any problems during transportation is available in real-time in the online-mode and thus enables for prompt actions to be undertaken to avoid food losses.

Relevant publications

- Jedermann, R.; Dannies, A.; Moehrke, A.; Praeger, U.; Geyer, M.; Lang, W.: Supervision of transport and ripening of bananas by the Intelligent Container. In: 5th International Workshop Cold Chain Management, Bonn, Germany, University Bonn, 2013. [

pdf]

pdf] - Jedermann, R.; Praeger, U.; Geyer, M.; Lang, W.: Remote quality monitoring in the banana chain. In: Philosophical Transactions of the Royal Society A, May/June 2014, Vol. 372(2017), 20130303. DOI:

10.1098/rsta.2013.303

10.1098/rsta.2013.303 - Mack, M.; Dittmer, P.; Veigt, M.; Kus, M.; Nehmiz, U.; Kreyenschmidt, J.: Quality tracing in meat supply chains. In: Philosophical Transactions of the Royal Society A, May/June 2014, Vol. 372(2017), 20130308. DOI:

10.1098/rsta.2013.0308

10.1098/rsta.2013.0308

Contact

Banana tests: Reiner Jedermann, Institute for Microsensors-, actuators and -systems, University of Bremen, ![]() Email

Email

Container refitting: Frank Husfeld, CHS Spezialcontainer - Shelter and Engineering GmbH, ![]() Email

Email

Meat tests: Judith Kreyenschmidt, University of Bonn, Institute of Animal Science ((ITW), ![]() Email

Email

Logistic processes: Marius Veigt, BIBA – Bremer Institut für Produktion und Logistik GmbH, ![]() Email

Email

Telematics, Cargobull Telematics GmbH, ![]() Email

Email