Poster Presentation at Model-IT

CFD modelling of deviating airflow and cooling conditions in banana containers

Model-IT Symposium on modelling for Horticulture

11-14. October 2015 in Wageningen, Netherlands

Reiner Jedermann and Walter Lang

CFD Modelling of deviating airflow and cooling conditions in banana containers

Temperature variations in reefer containers with fruits regularly occur due to deviating airflow and cooling conditions (DACCs). DACCs are mainly caused by irregular width of gaps. The effect is enhanced by biological variance of respiration activity.

There is little knowledge whether DACCs affect only a small area or the complete container load. During 7 tests in containers from Costa Rica to Europe since 2009 we observed a high level of spatial temperature variation inside the container. Bananas pallets are neither in perfect rectangular shape nor completely fit the inward container dimension, resulting in gaps with a range from almost completely closed to about 6 cm. The experimental data verified a strong relation between gap width and temperature in neighboring boxes. Due to the restrictions in a commercial cold chain, we were not able to tests the effect of different DACCs in isolation or separate local and container-wide effects.

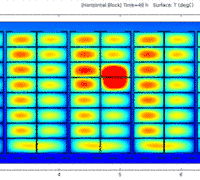

We set up a Computational Fluid Dynamics (CFD) simulations (COMSOL) for the air flow and temperature in a container loaded with bananas to provide a better understanding of DACC effects. Due to the complex geometric of a container with 960 boxes and narrow gaps, the simulation had to be reduced to a 2-dimensional (2D) model, consisting of a row of 10 pallets.

A detailed 3D model for a single box will be published separately. The thermal conductivity of air-banana mix inside the box was modified for a 2D model. Further parameters were tuned to give a good match between the simulation and field test data.

Almost all DACCs had a predominant local effect with high temperature peaks: Poor cooling of last pallet at door end due to missing foam block (+5.78°C higher 48 hours after start of cooling), horizontal blocking inside one pallet (+4.64°C), gap of 10 cm between two pallets (+3.48°C), and double biological activity in 6 boxes (+2.60°C).

The effect on the average container temperature was in most cases below 0.1°C with only few exceptions: Reduced inlet air-speed by 20% (+0.596°C), and short-cut of airflow by missing foam block or large gap between pallets (+0.513°C / +0.248°C).

The simulation also showed a large horizontal variation inside the pallets with the side towards the cooling unit in average 1°C warmer that the door side. This effect was much larger than variation in the experimental data, but could not be avoided due to the reduction to a 2D model.

Although a reduced 2D model cannot provide an exact temperature prediction, it leads to a better understanding of DACC effects:

- DACCs lead to high temperature peaks of several degrees Celsius. Overlapping of two DACCs can generate a hot-spot, which generates more thermal energy than can be removed by cooling.

- A reliable detection of DACCs is only possible with a high number of temperature measurement points. Otherwise DACCs will be missed due to their local nature.

- The spread of a hot-spot over the whole container, which is the major risk in banana transportation, cannot be explained by local thermal effects alone.